- +91-9334112614 +91-7091195001

- info@tubexindia.com tubex.indiapvtltd@gmail.com

- Head Office Shree Baidyanath Ayurved Bhawan, Baidyanath Bhawan Road, Patna : 1

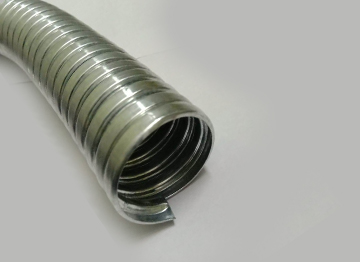

Tubex Make Heavy Duty SAPA Conduit

| Product | : | Galvanised Steel Flexible Conduit |

| Construction | : | Helically Wound Square Lock Flexible Conduit |

| SelfColour | : | Silver |

| Raw Material | : | Pre Galvanised Steel Z120 GSM Which Corresponds average coating weight of 120gsm of surface area as basic core material |

| Marking & Packing | : | Flexible Conduit & Adaptors are paked with our logo and also as per costomer Request Strong hdpe bags and white page box. |

| Cutting | : | We recommend use of fine tooth 32tpi Hacksaw short conduit length can be readly in corporated |

| Standard Approvals | : | All Condults are manufactured in accordance to IS-3480 Certified: NABL INDIA. |

| IP Rating | : | IP40 with standard fittings |

| Aluminium | : | Male Adaptor with male metric Thread with G.I or Brass Locknut |

| Brass | : | Male Adaptor with Male Metric Thread with G.I. or Brass Locknut. All Adaptors or manufactures to a fine tolerance to ensure a very tight fit with ease of removal flexibles conduit. |

| Material | Galvanized Steel Or Stainless Steel |

| Profile | Flat Square lock |

| Strip Used | Mild Steel, Bright, Cold Rolled and annealed, at least equivalent in quality to Grade EN 2 and specified in IS : 513. Stainless Steel Grade : AISI 304 / AISI 316 |

| Galvanize Coating | MS Conduit : 12 - 15 Micron minimum Stainless Steel : Bright Mirror Finish. |

| Uses | Square lock provides protection for wring circuits located in extremely wet or damp areas. It is also suitable for machine, equipments where ruggedness is required and blowers, grinders, conveyors, automated lines, construction, industry and transportation. |

| Packing | Standard package shrink wrapped coil in bag. |

ID Nominal in mm(Size) |

Tolerance on ID in mm |

O.D. Max in mm |

Minimum Bending Radius in mm |

Minimum Linear Breaking Load in Kgf. |

Minimum Bend fracture load in Kgf. |

Length in Meters. OR Customer Choice |

6.5 |

± 0.5 |

9 |

28 |

35 |

11.5 |

35+ |

10 |

± 0.5 |

13 |

30 |

60 |

18 |

35+ |

12 |

± 0.5 |

16 |

32 |

78 |

22 |

35+ |

16 |

± 0.5 |

20 |

45 |

110 |

35 |

30+ |

19.5 |

± 0.5 |

23 |

60 |

140 |

38 |

30+ |

25 |

± 0.5 |

31 |

75 |

180 |

40 |

15+ |

30 |

± 0.5 |

35 |

85 |

250 |

53 |

15+ |

40 |

+ 1.0 |

46 |

120 |

330 |

70 |

15+ |

50 |

-do- |

58 |

130 |

385 |

98 |

10+ |

63 |

-do- |

70 |

178 |

430 |

125 |

10+ |

75 |

-do- |

82 |

190 |

435 |

130 |

10+ |

100 |

-do- |

108 |

250 |

500 |

190 |

10+ |

| Com Part # | Size | Internal Diameter (MM) | External Diameter (MM) | Min. Bend Redius (MM) | Coil Packing (Mtr) | Sheet Thickness |

| TIPL-101 | 3-8" | 10 | 13 | 30 | 15,25,30 | 0.25 |

|---|---|---|---|---|---|---|

| TIPL-102 | 5-8" | 16 | 19 | 30 | 15,25,30 | 0.25 |

| TIPL-103 | 1/2" | 13 | 17 | 43 | 15,25,30 | 0.25 |

| TIPL-104 | 3/4" | 19 | 23 | 50 | 15,25,30 | 0.25 |

| TIPL-105 | 1 | 25 | 29 | 57 | 15,25,30 | 0.35 |

| TIPL-106 | 11/4" | 32 | 36 | 70 | 15,25,30 | 0.40 |

| TIPL-107 | 11/2" | 38 | 43 | 80 | 15,25,30 | 0.50 |

| TIPL-108 | 2" | 50 | 55 | 95 | 15,25,30 | 0.50 |

| TIPL-109 | 21/2"" | 63 | 70 | 140 | 7.5,15 | 0.50 |

| TIPL-110 | 3" | 78 | 85 | 150 | 7.5,15 | 0.60 |

| TIPL-111 | 4" | 101 | 109 | 190 | 7.5,15 | 0.70 |