- +91-9334112614 +91-7091195001

- info@tubexindia.com tubex.indiapvtltd@gmail.com

- Head Office Shree Baidyanath Ayurved Bhawan, Baidyanath Bhawan Road, Patna : 1

Our team of experts monitor and log each and every step of processes to fulfil our quality promise to our customers. Superior quality product and procurement of best quality raw material is available only due to quality control checks made by agents. Our quality controllers use advanced technology and their technical expertise to optimize quality of our products. Tubex follows Quality Management System and holds ISO 9001 : 2008 certification also. Our name is counted as a prominent manufacturer and exporter of a wide range of flexible metal tube, flexible metal pressure tube, PVC coated tube, conduit and rubber hoses for fuel oil handling system etc.

Tubex Flex strip wound metallic interlock hose are manufactured in accordance with generally standards ISO 15465 : 2004 & British Standard BS 6501- PART II.

ISO STANDARD: 15465-2004 This International Standard specifies the requirements for the design, manufacture and testing of four principal types of strip wound metal hose and hose assemblies, of which only one type is for pressure applications. The four are: single overlap, unpacked and packed; double overlap, unpacked and packed, the last of these having maximum allowable pressures of up to 40 bar, These hoses and hose assemblies may be supplied in nominal sizes from DN 6 to DN 500 and may operate at temperatures up to 600 °C dependent on materials of construction.

International Title : Pipe work – Strip wound metal hoses and hose assemblies (ISO 15465: 2004). Approved dated : ......

ROHS Compliance : Our Interlock Hoses are under ROHS Compliance Test Certificate are Issued along with the material If required.

ROHS Compliance Definition : The definition and aim of the ROHS directive is quite simple. The ROHS directive aims to restrict certain dangerous substances commonly used in electronic and electronic equipment. Any ROHS Complaint component Tested for the presence of Lead (Pb), Cadmium (Cd), Mercury (Hg), Hexavalent chromium (Hex-Cr), Polybrominated biphenyls (PBB), and Polybrominated diphenyl ethers (PBDE). For Cadmium and Hexavalent chromium, there must be less than 0.01% of the substance by weight at raw homogeneous materials level. For Lead, PBB, and PBDE, there must be no more than 0.1% of the material, when calculated by weight at raw homogeneous materials. Any ROHS compliant component must have 100 ppm or less of mercury and the mercury must not have been intentionally added to the component. In the EU, some military and medical equipment are exempt from ROHS compliance.

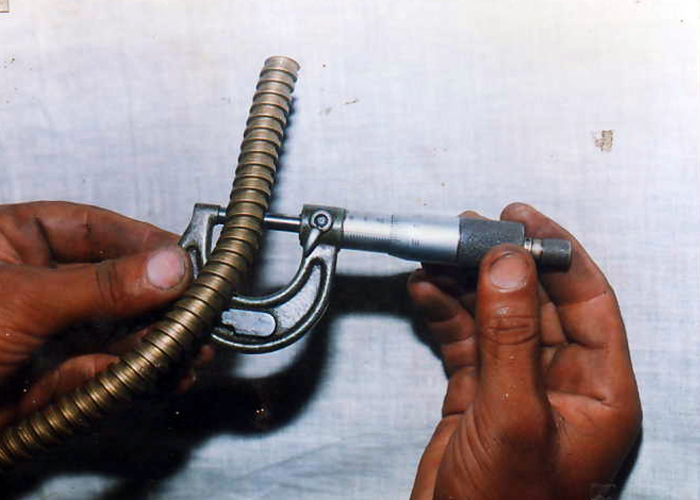

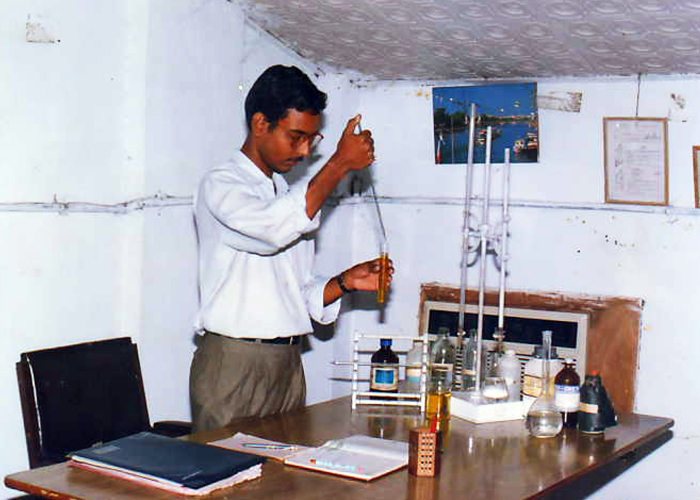

A test of attributes that are assessed to ascertain the quality of our range Metallic interlock Flexible Hoses & Conduits:

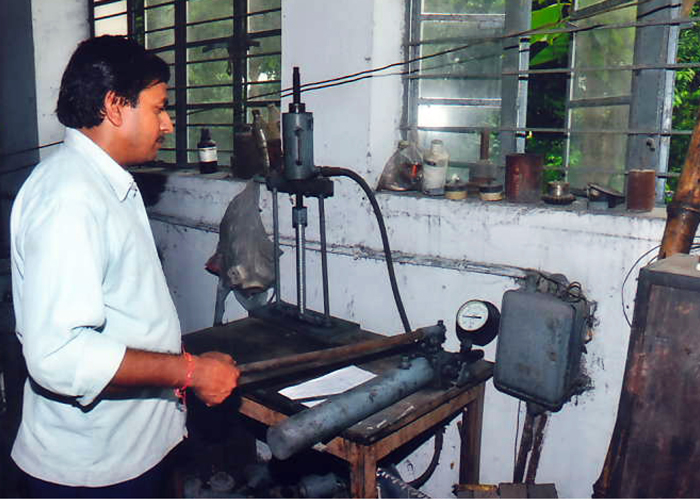

Every Strip wound Interlock Pressure & Exhaust hose assembly is tested hydraulically according to required working pressure in different sizes before dispatching. Smoke Test is also carried out whenever necessary to detect the leakage in exhaust hoses. All raw material used in the manufacture of interlock hoses, and end-connections undergo rigid inspection by qualified Inspectors to ensure highest quality standards produced gives the best performance for many years.

Besides stringent in-house control of quality, raw materials are sourced only from reputed manufacturers and these are regularly counter checked from external independent agencies for physical, chemical and metallurgical properties.

Where a general material certification is required, Tubex Shall provide letter of Conformity, Which shall confirm the grade & strip thickness of materials is used in manufacturing strip wound interlock hoses in both Stainless Steel & Galvanized Steel.